For the overwhelming majority of frequent flyers, air journey is related to a lot of inconveniences and discomforts. We do it as a result of now we have to, not as a result of we need to—all of which displays an trade that maximizes effectivity, not comfort. However for these fortunate sufficient to journey in enterprise or first-class, these compromises don’t remain on the tarmac, with a Group 1 seat ticket promising elevated ergonomics, superior supplies, considerate design and enjoyable in-transit expertise. Caon Design Bureau and of Woolmark Modulo The plane seating idea envisions an aesthetically efficient technique of permitting airways to refresh their cabins on the fly – with out a premium price ticket – by combining consolation and practicality with a modular design.

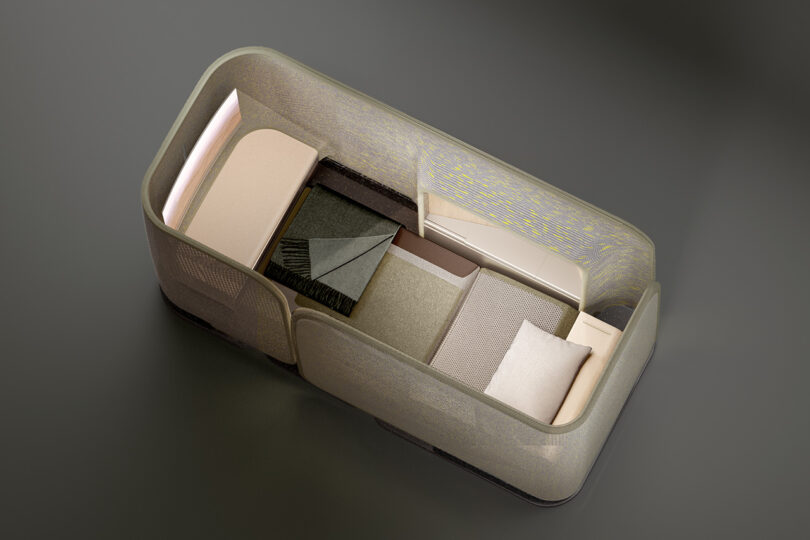

Not like present merchandise, which regularly depend on onerous composites or plastics for bulkheads and seats, Modulo makes use of wing-like wool parts, thus concentrating on one materials as a central design theme.

The Modulo plane seat design idea, conceived by Caon Design Workplace and Woolmark, is straight addressing the sensible points related to air transport – weight discount, sustainability and the necessity to deal with deliberate cabin refreshment. They seem to have met these wants by utilizing a 3D-woven wool-blend membrane stretched over a titanium, aluminum, and carbon fiber body. On this manner, Caon’s Modulo maintains a light-weight footprint on the plane whereas softening all of the contact zones a passenger might expertise upon boarding, within the air and upon arrival.

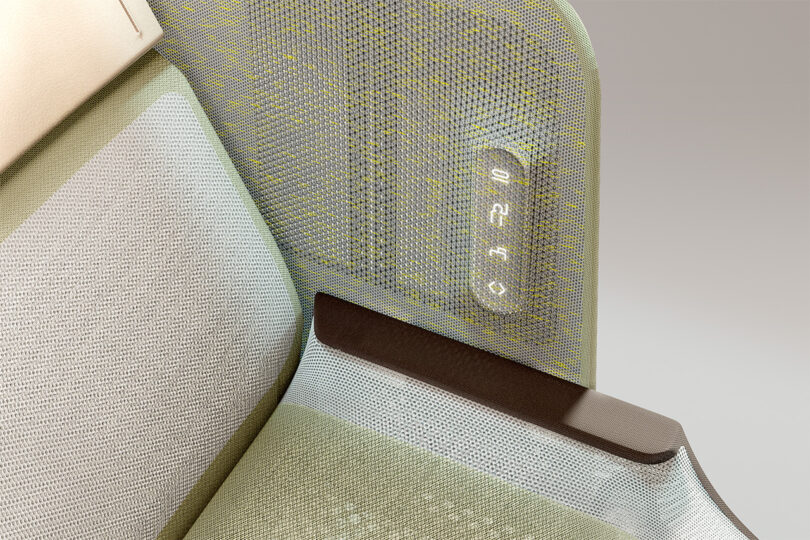

Modulo’s design is intelligently built-in with sensors and expertise to boost passenger consolation and security. These gadgets actively monitor and regulate seat temperature for optimum consolation. In addition they maintain passengers shifting periodically, options particularly geared toward mitigating well being dangers related to extended immobility, comparable to deep vein thrombosis.

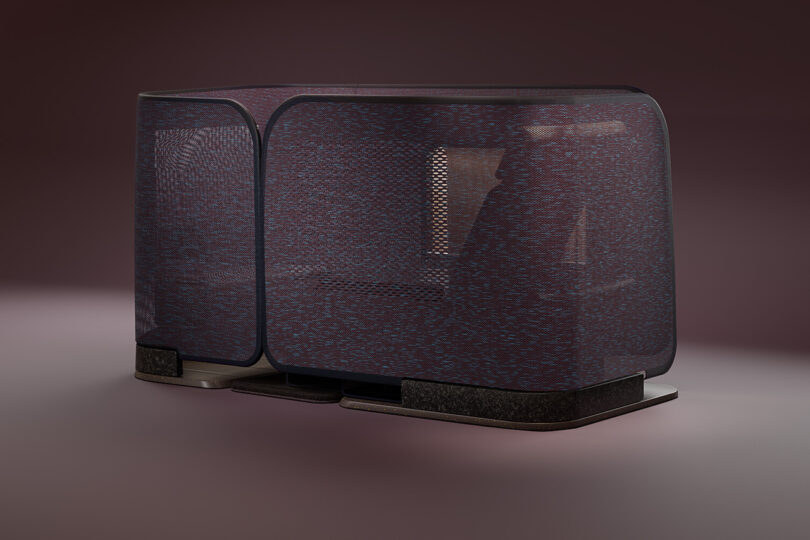

Caon partnered with Woolmark, citing the corporate’s Australian merino wool as the best materials for its softness, energy, innate flexibility, technical benefits and 100% pure, renewable and biodegradable fibre.

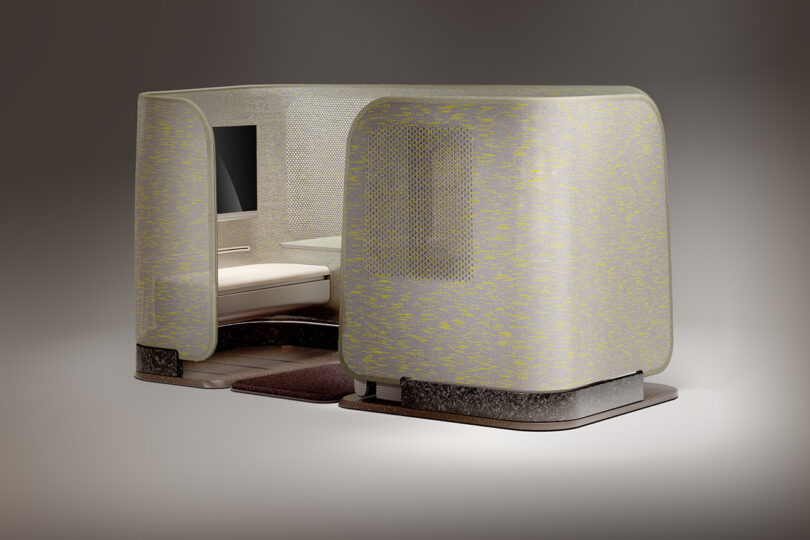

“In exploring the right way to increase the capabilities of wool fibers inside airways, we’re addressing a significant downside for airways, as they should spend big quantities of time and money to vary the texture of their cabin interiors,” notes David Caon . “Passengers additionally profit by having extra of this glorious materials that breathes and permits us to play with mild and opacity to create new eventualities for privateness and leisure.”

Conceptualized as a 3D-knitted wraparound shell, Modulo’s wool-blend construction is translucent, giving passengers a softer transition from the open area of the airplane into a personal enclosure with out feeling fully enclosed. As an alternative of conventional foam, Modulo’s wool mix development permits for wadding in sure areas of the material the place a thicker, denser and sound/vibration absorbent half is required.

“By harnessing the advantages of Merino wool, comparable to breathability, moisture wicking properties and opulent softness, Modulo demonstrates how Merino is uniquely positioned to raise the way forward for journey by way of unparalleled consolation and improved sustainability,” mentioned John Roberts, Managing Director, Woolmark.

From a sensible standpoint, Modulo’s light-weight modular design permits airways the flexibility to refresh their cabins with seasonal themes or up to date branding initiatives with out prolonged downtime. Your entire seat meeting is constructed with a fast launch mechanism and the wool membrane pores and skin might be changed as simply as a typical seat cowl.

Caon emphasizes that the Modulo idea is relevant not just for air transportation, but additionally as a seating answer adaptable to all technique of “mass transit, hyperloops, autonomous automobiles and electrical planes.” With its promise of great weight discount, improved sturdiness and lowered gas consumption, the 3D-woven textile membrane seats look like a premium thought with economy-class efficiency and a refreshingly fashionable aesthetic.

To study extra about inventive options from Caon Design Workplace caondesignoffice.com.